Industrial Waste Water or Effluent Treatment Systems – Chemical Methods

Effluent treatment chemicals are commonly used to clean industrial wastewater. One method of using effluent treatment chemicals is the biodegradation process. This process uses biological agents to break down the pollutants in the water.

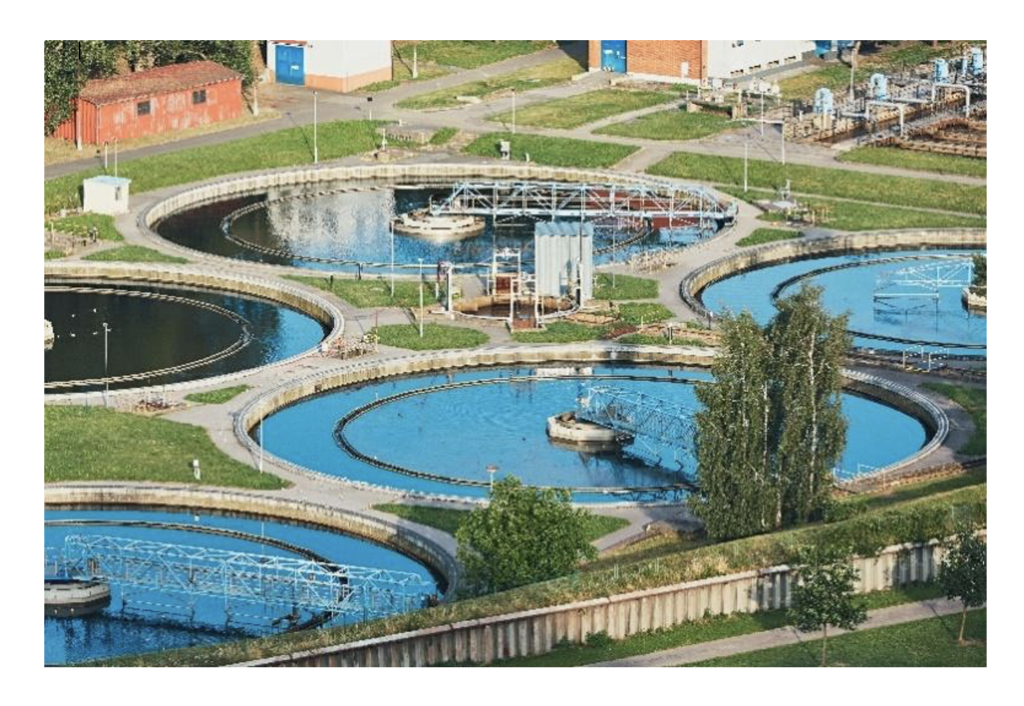

Industrial water treatment

| Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment.

Wastewater treatment Wastewater treatment is a process that removes and eliminates contaminants from wastewater and converts this into an effluent that can be returned to the water cycle. |

|

Industrial wastewater treatment describes the processes used for treating wastewater that is produced by industries as an undesirable by-product. After treatment, the treated industrial wastewater (or effluent) may be reused or released to a sanitary sewer or to a surface water in the environment.

Wastewater treatment

Wastewater treatment is a process that removes and eliminates contaminants from wastewater and converts this into an effluent that can be returned to the water cycle.

Effluent Treatment Processes

|

There are many effluent treatment process technologies available to industrial plants. Each technology has its own advantages and disadvantages. The most common effluent treatment technologies are listed below: |

Chemical Method of Effluent Treatment

Effluent treatment refers to a system used to reduce the toxicity and harmful components of wastewater effluents. One common method for effluent treatment is chemical treatment, which involves the use of chemicals to decompose or destroy waste materials. Chemical treatments can be divided into three main categories: primary, secondary, and tertiary treatments.

Primary treatment removes large particles from water by using physical filters such as settling tanks or cascades. Secondary treatment uses chemicals to oxidize pollutants so they cannot bioaccumulate in organic matter or dissolve into groundwater supplies. The tertiary treatment combines various forms of effluent treatment chemicals to break down the effluents and pollutants. The following are some of the most common types of effluent treatment chemicals:

- Activated carbon filters

- Particulate interceptors

- Ultraviolet radiation

Physical Method of Effluent Treatment

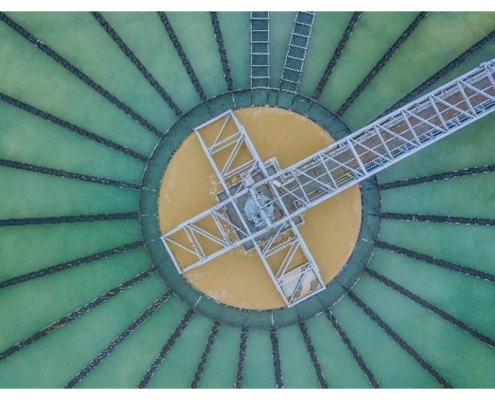

Physical methods, such as sedimentation and flocculation, can be used to remove suspended solids from effluent. These processes use energy to break down the particles into smaller pieces that are then removed from the water.

Physio-chemical Method of Effluent Treatment

| Effluent treatment chemicals (ETCs) are used to treat wastewater and effluent in industrial processes. They are used to reduce or neutralize pollutants, including bacteria, metals, organic materials, and toxins.

Chemicals that have been used as ETCs include chlorine dioxide (ClO), ozone (O3), hydrogen peroxide (H2O2), particulate matter filters such as activated carbon (AC), and granular activated carbon with anthracite coal ash(GAC-A). |

|

Biological Method of Effluent Treatment

One of the most effective ways to treat effluent is through biological means. Biological treatment converts organic materials into hydroxides and acidity levels that are less harmful to the environment. This process can be very efficient, with some systems able to remove 80-90% of pollutants from water. However, it is also more expensive than other effluent treatment methods and requires regular maintenance.

WATER SCARCITY

There is a water scarcity issue in many parts of the world, including India. This can affect the ability to treat effluent from industrial processes with chemicals.

WATER POLLUTION

Water pollution is the contamination of water bodies with substances that are hazardous or detrimental to human health and the environment. Sources of water pollution can include sewage treatment plants, agricultural runoff, chemical facilities, and automobiles.

Many pollutants originate from domestic effluents such as wastewater, cooking oil, and soap scum. Industrial effluents like production waste streams and acid rain come from manufacturing processes. Marine debris includes everything from fishing nets to derelict vessels that have sunk into coastal waters leaving behind materials such as plastics and paint which can harm marine life.

WATER CYCLE AND THE CAUSES AND EFFECTS OF WATER POLLUTION

Water pollution is the result of activities that contaminate water with pollutants. The most common sources of water pollution are factories, sewage plants, and automobiles. Pollution can come from numerous sources including wastewater treatment plant effluent, agricultural runoff, oil spills, and manufacturing waste products.

Some pollutants in water can cause health problems such as skin rashes or respiratory illness. Water also contributes to climate change by serving as a carrier for toxins and carbon dioxide emissions. Proper management of resources like treated wastewater can help Reduce environmental impacts while ensuring safe drinking water supplies for communities.

Wastewater Treatment – Role of Sludge Conditioners

The effluent treatment plant operator must be familiar with the role that sludge conditioners will play in wastewater treatment. Sludge conditioners are used to treat sewage and agricultural waste before it is discharged into waterways or landfills.

Some common types of sludge conditioners include:

- Alkalizers – These devices make water more acidic by breaking down organic molecules into smaller pieces. This makes it easier for bacteria to convert these molecules into energy, which then helps break down pollutants in the sewage.

- Denitrifiers – De-nitrifiers take nitrogen out of the air

Tertiary Wastewater Treatment by Activated Carbon

Activated carbon is a natural material made of tiny pieces of charcoal. When water is passed over the activated carbon, it forms molecules called “carbon dioxide” and “oxygen”. This process helps to treat water with harmful contaminants.

Activated carbon filtration is a commonly used technology based on the adsorption of contaminants onto the surface of a filter. This method is effective in removing certain organics (such as unwanted taste and odors, micropollutants), chlorine, fluorine or radon from drinking water or wastewater. However, it is not effective for microbial contaminants, metals, nitrates, and other inorganic contaminants. The adsorption efficiency depends on the nature of the activated carbon used, the water composition, and operating parameters. There are many types of activated carbon filters that can be designed for household, community, and industry requirements. Activated carbon filters are relatively easy to install but require energy and skilled labour and can have high costs due to the regular replacement of the filter material.

Coagulation, Flocculation and Sedimentation

Effluents are used in the treatment of chemicals, water and soil. Flocculation and sedimentation can be used to separate contaminants from effluent.

Filtration

Effluent treatment chemicals are filtered through either a 0.22-micron filter or a more specific 0.1-micron filter in order to remove any large pieces of debris that may be left over from the effluent treatment process.

Particle filtration is a physical or mechanical process that separates solids from fluids. Particle filtration typically is defined as the filtration of particles larger than 1 micron and is used as one of the first filtration steps in industrial wastewater treatment. Common technologies that are used for fine-particle filtration include bag filters, cartridge filters, multimedia filters, and self-cleaning filters.

Because industrial wastewater characteristics can vary so dramatically, depending on the industry, it is common to use multiple technologies to process the water. The properties of the solids in the water, including particle size, shape, density, stickiness, and quantity, as well as other materials in the water such as oil, determine which filter technologies are used.

The water quality is described in terms of total suspended solids (TSS) in units of milligrams per litre (mg/l). The TSS level helps to determine which filtration technology to use. Additional information such as the particle size distribution and particle shape can help to identify the appropriate technology to use and the correct filter cut-off. For example, if the particle sizes range from 20 to 80 microns, then a 20-micron or lower filter cut-off would remove 100 percent of the particles.

Aeration

The effluents from commercial and industrial plants can contain high levels of solids, VOCs and other pollutants. The treatment of these effluents is an important step in reducing the environmental impact. One common method used to treat these effluents is aeration. Aeration breaks down suspended materials into smaller pieces that can be removed by the plant’s wastewater treatment system.

Industrial Wastewater Treatment

Effluent treatment chemicals are used in industrial wastewater treatment to remove pollutants. Waste effluent is treated with a combination of physical, chemical and biological processes to achieve compliance with environmental regulations.

Questions:

What chemicals are used in STP?

Effluent treatment chemicals include various solvents, desiccants and ultraviolet light.

· pH neutralization of water

To control better, the pH level of the wastewater, basic chemicals such as alkalis and other acidic acids can be added to the water.

· Use of chemical precipitation to remove heavy metals

Chemical precipitation is a method of removing heavy metals from wastewater. To avoid contamination, add the precipitation reagent to the water. To form solid particles, heavy metals are ionically bonded with the reagent. Filtration is then used to eliminate these solid particles from the water.

· Chemical coagulants

Chemical coagulants are chemicals based on aluminium or iron that aid in the removal of pathogens, fluoride, organic compounds, and other pollutants. They work to destabilize wastewater particles by presenting a positively charged coagulant that reduces the particles’ negative charge. Waste particles aggregate to form larger bodies that can be purified.

· Flocculation of wastewater/sewage

Through charge bridging and magnetic neutralization, flocculants aid in the removal of very fine particles from wastewater treatment plants. Waste particles are encouraged to form clumps or flocs that can settle out during the sedimentation process with the addition of flocculants.

· Removal of odor

Certain toxic contaminants frequently cause the water to smell bad. To keep the water scented fresh, effective wastewater treatment methods include the use of iron salts, biofiltration, oxidants, and other technologies.

· Cleaning and de-greasing chemicals

Water in a wastewater treatment plant includes oil and grease residue that must be processed before being released back into the environment. Solvent chemicals can aid in the breakdown of grease, making it easier to eliminate.

· Chemical oxidation process

Chemical oxidation is a process used in wastewater engineering to convert pollutants into less harmful compounds. This contributes to the purification of surface waters. To reduce the impact of hydrogen peroxide, chlorine antibiotics, and other compounds in the water, reducing agents such as sodium bisulfite, sodium hydrosulphite, and other chemicals are used.

· Use of de-foamer and anti-foamer for wastewater

A defoaming agent is a chemical preservative that aids in the reduction of trapped air and foam produced during the wastewater treatment process. Defoaming agents dissolve existing foam, while antifoaming agents prevent new foam from forming. The most common application of silicone is as a defoaming agent.

What are the effluent treatment systems?

The effluent treatment systems are machines and processes used to remove pollutants from wastewater. The main types of effluent treatment systems are biological, chemical, and physical. Effluent treatment systems are used to clean water before it is discharged into the environment.

The effluent treatment facility is installed for the biological treatment of the effluents. The effluent bears large amounts of organic matter. The direct discharge of the effluent into the water bodies causes depletion of DO of the water. Hence, in order to meet the recommended standards of quality of the effluent, it is necessary to treat the effluent before it is finally disposed of. This treatment facility provides for the removal of major pollutants from the effluent.

People Also ASK

What are the primary purposes of wastewater treatment plants?

The primary purposes of wastewater treatment plants are to remove contaminants from water and to produce water that meets quality standards for the reuse of water in processes and operations.

Which chemicals are used in effluent treatment as coagulants?

General and 7 most used coagulants in the water treatment plant is under:

- Alum (aluminum sulfate), Al2(SO4)3. Still, the most common coagulant in the United States, it is often used in conjunction with cationic polymers.

- Poly aluminium chloride, Al(OH)x(C1)y. This is efficient in some waters, requiring less pH adjustment and producing less sludge. (simply called PAC)

- Ferric chloride, FeCl3. This may be more effective than alum in some applications.

- Ferric sulfate, Fe2(SO4)3. It is effective in some waters and more economical in some locations.

- Ferrous Sulfate, FeSO4. It costs a bit more compare with ferric chloride, but the result would be better than that

- Sodium Aluminate, Na2Al2O4

- Cationic polymers can be used alone as the primary coagulant or in conjunction with aluminum or iron coagulants.

Nowadays most of plants are using Cationic polymers, and the cost is high compared with inorganic coagulants. But it can be used with a wider pH range and produce less sludge.

The choice or selection of a coagulant chemical depends upon the nature of the suspended solid to be removed, the raw water conditions, the facility design, and the cost of the amount of chemical necessary to produce the desired result.

Which chemicals are used in effluent treatment as flocculants?

To select a flocculant, consider the following factors:

- Type of suspended particles: Different flocculants are effective for different types of particles, so it’s important to identify the composition of the particles to be treated.

- pH level: The pH level of the water or wastewater can impact the effectiveness of the flocculant, so it’s important to determine the pH level before selecting a flocculant.

- Dosage: The dosage of flocculant needed will depend on the concentration of suspended particles and the desired level of clarification. Lab testing should be conducted.

- Compatibility with other chemicals: If other chemicals are being used in the water or wastewater treatment process, it’s important to select a flocculant that is compatible with these chemicals to avoid any negative impacts.

- Cost: The cost of the flocculant is an important consideration, especially for large scale operations.

- Environmental impact: Consider the environmental impact of the flocculant, including any potential toxicity and biodegradability.

How Advance Chemicals can help in your quest to find the right Effluent Treatment chemicals or Waste Water Treatment Chemicals?

A variety of effluent treatment chemicals are available to help you manage wastewater and industrial effluents. These chemicals can be used alone or in combination, depending on the specific needs of your plant.

Some common types of effluent treatment chemicals include alkalinity adjusters, disinfectants, odour control agents, solvents, and flocculants. Depending on the type of pollutant being treated and the severity of the situation, a range of treatments may be necessary (from simple maintenance procedures to more extensive engineering solutions).

Our team of experts, who specialize in environmental protection, will analyse the wastewater streams both qualitatively and quantitatively. On basis of the analysis, we will recommend stage-wise chemical inputs and will ascertain the adequacy of the installed equipment as well. We will be able to predict the outcomes with up to 99% accuracy.

We boast of a vast research-based manufacturing unit and thus have a state-of-the-art laboratory facility. We can even customize chemicals to suit your best needs.